The Destructive Power of Cavitation

Breaking Dishes in Iso Tanks; The Background

Ever since the release of the Control Tower, we've unjustly caught some flack here at Highly Educated. The issue was; customers would dunk their Control Tower into alcohol, they would hear a pop upon submission, and they would remove their Tower to find a crack in the dish or even the dish separated. Very frustrating for every party involved as the customer will want to blame us the manufacturer and we tend to want to lay blame on things like thermal shock or falling marbles. No one wants to be at fault. It's human nature. Despite the frustrations we have done our best to service those customer issues up until today and we have worked to improve the part and discover why the issue was occurring. We are now confident we have found both the cause of the cracks, the breakage and the solution. It is a quartz maintenance tip that no one has ever talked about until now because, as far as we know, no one knew it was happening.

Make The Part Fail

When conducting the destructive thermal shock tests we observed that parts would experience loud pops when inserted into the iso tank in a horizontal, laying down position. A part that was taken to 500 F and dunked upright, vertically did not experience any popping noise but that same part inserted into the tank horizontally would exhibit two to three loud pops during its dunk. This horizontal dunk process was then repeated over and over until eventually we were able to replicate both the cracks and breaks that our customers had been experiencing. The conclusion of the test confirms that thermal shock was not actually the cause of any dunking failure but instead a much more powerful, previously undiscussed, force of cavitation was in fact to blame.

Vapor Pressure:

When the Tower is dunked into the Tank, if it is hot enough to boil the alcohol, vapor will be produced upon submersion. As vapor is produced the vapor pressure in the system increases. If the Tower is upright the system is open and the vapor pressure can escape. If the Tower is horizontal, or partially upside down, this vapor pressure can not readily escape the system. As these vapor bubbles coalesce they begin to form a larger void. This void will grow until the local pressure of the liquid exceeds the vapor pressure of the void. Once this occurs, the void collapses producing a jet-stream and a shockwave in a phenomena known as cavitation.

Cavitation:

Cavitation is the formation and subsequent collapsing of bubbles in a liquid. These bubbles, sometimes referred to as voids, form when a liquids pressure drops below the vapor pressure. When the liquids pressure exceeds the vapor pressure these bubbles will collapse creating jet-streams, shockwaves, and extreme temperatures (up to four times hotter than the sun) that are capable of damaging parts.

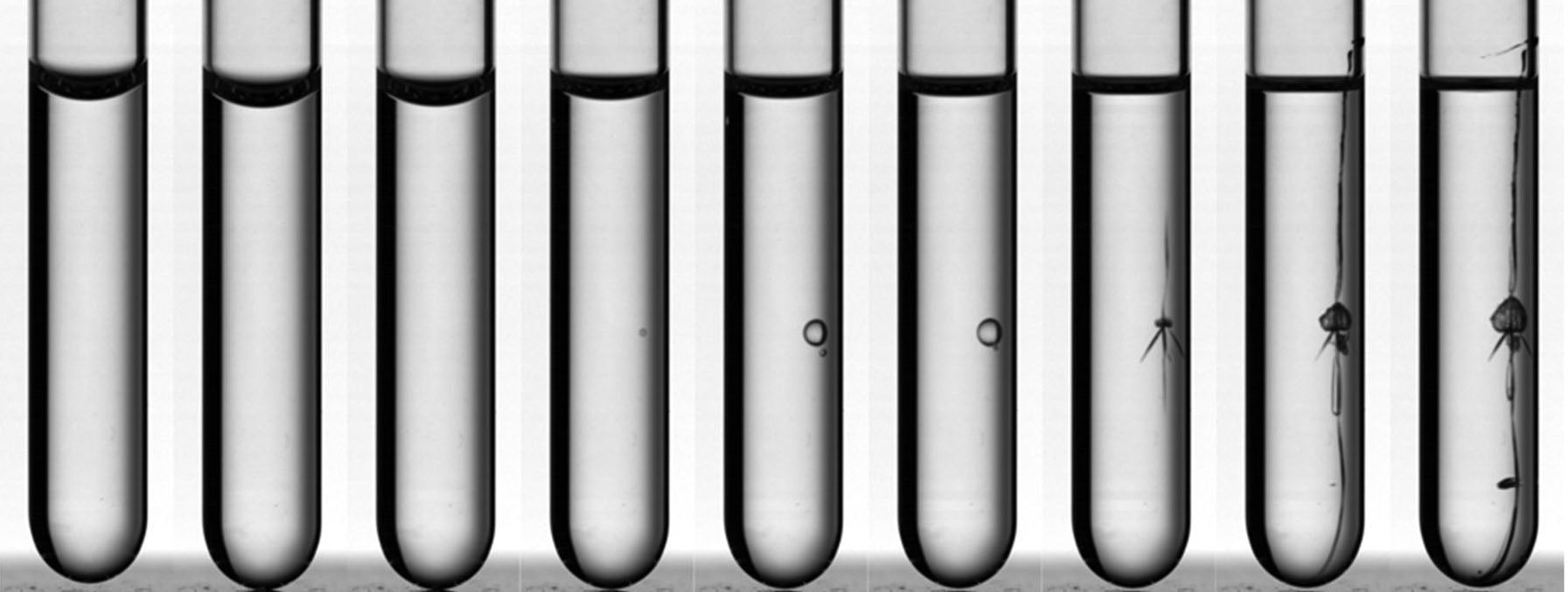

In the video above, the cavitation bubbles are created using a quick pressure differential. As the pressure stabilizes in the bottle the bubbles collapse creating a shockwave with enough force to break the bottle. This varies slightly from our discovery where we found that the bubbles formed from boiling can coalesce into a larger bubble that itself is susceptible to cavitation. These shockwaves occurring at or near the surface are detrimental to the glass.

How To Avoid Cavitation

The best way to avoid cavitation is by dunking at a temperature that doesn't produce alcohol vapor. However we realize this doesn't dissolve the reclaim as readily and people don't like waiting to dunk so the second best way to avoid cavitation is by dunking the Control Tower in an upright position so that the vapor pressure can escape the system. If the opening of the Tower stays above the liquid, then there should be no reason for the cavitation to occur. Once all the pressure has escaped the system you can fully submerge the Tower.

Closing Remarks

As I said previously, this has been a frustration for all parties involved. We are happy to have finally been able to discover the cause of the issues. We hope that with this education put into action less people will experience this part damaging phenomena. It is totally avoidable, so spread the good word: the latest quartz maintenance tip is dunk it upright vertically. If you have experienced a cavitation issue feel free to reach out to us to see what possible service options are available.