Introducing the Gavel SE - Surface Enhanced.

Introducing The Gavel SE.

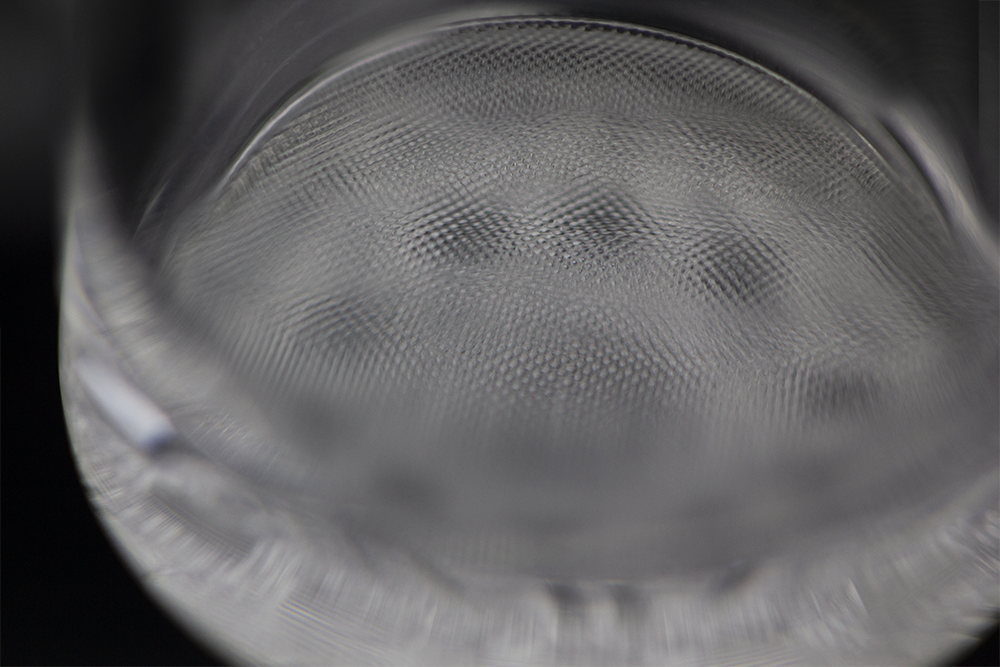

Modifying a surface to enhance its performance is nothing new. It's been studied in academic literature, it's been deployed in products through out many industries to improve efficiency, biocompatibility, wettability, adhesion properties etc. With our introduction of opaque quartz to the dabbing industry, we discovered that by intersecting a bubble cell on the surface we created cavities which ended up boosting the nucleation that took place on the surface. Today in the dabbing world, surfaces are being purposefully manipulated in an attempt to further bolster efficiency.

How does a surface enhancement boost efficiency?

Surface enhancement can boost efficiency in many ways some of which are:

1. Increase in surface free energy. A smooth surface will have the surface area of its geometrical shape. Surface modification allows the material to have a surface area much greater than the geometric one. With an increase in surface area, comes an increase in surface free energy.

2. Lowering liquid surface tension. Surface tension is the tendency of liquid surfaces at rest to shrink into the minimum surface area possible. By increasing the surface free energy of the quartz the surface tension of the applied liquid is lowered which;

3. Promotes wetting. Wetting is the ability of a liquid to maintain contact with a solid surface, resulting from intermolecular interactions when the two are brought together. The degree of wetting is determined by a force balance between adhesive and cohesive forces. Wetting and the surface forces that control wetting are also responsible for other related effects, including capillary effects.

4. Increased nucleate boiling. The inclusion of nucleation sites evenly distributed across the surface helps advance the onset of the nucleate boiling and increases the amount of sites across the floor in which vapor may be freely produced during that phase of vaporization. The bubble creation process starts with a dry floor which once made wet is dried again as a vapor bubble grows; until the bubble reaches a critical radius and disconnects from the floor. Then the process repeats until the surface free energy is expended and the site on the floor stops boiling. But not all vapor is produced during the nucleate boiling phase, most of it is produced in the evaporation/drying phase when no boiling is occurring at all.

5. Advances evaporation/drying times. Evaporation occurs when a liquid changes to a gas at a temperature below its boiling point. It is the dry areas of the surface that have enough free energy to produce the phase change from liquid to vapor in both boiling and evaporation. By advancing the evaporation/drying time of the surface, we increase the amounts of vapor that can be produced at the tail end of the temperature spectrum. This helps to more efficiently achieve complete vaporization.

Watch the demonstration video below to see these forces in action.

But there are some caveats to surface enhancements that we have learned, and we will address them here.

1. Cleanability: Intuitively, the further a surface deviates from perfectly smooth the harder it becomes to clean. Users of the opaque are familiar with both the increased functionality and difficulty of maintenance in comparison to a smooth clear surface. With the Gavel SE we have developed a surface that has the visual luster of clear quartz, that gives the kind of experience opaque Gavel users have grown to love, but cleans up much more like a clear nail than an opaque one. Maintenance can be managed without iso alcohol when used and cleaned properly which differs from the opaque which required iso alcohol to avoid black spots from developing in the materials cavities.

2. Durability: Through our extensive testing on different patterns of size, shape, and texture we have found durability to be an issue with certain designs. Nano and micro sized structures developed via processes like deep reactive ion etching (or similar) are susceptible to melting in the manufacturing process. Protruding structures that survive manufacturing wouldn't pass a wire brush test. Any sized protrusion of material will be susceptible to breakage from outside mechanical forces such as cotton swab friction, dabber contact, and other normal use actions. By having no structures on the surface of the floor, durability is significantly increased and not likely to suffer any long term structural failure.