Quartz, Fused Quartz, Fused Silica, What's the Difference?

What is Quartz?

Quartz is a term used to describe many different compact forms of SiO2. As one of the second most common and varied minerals on earth, its abundant and can be found in crystalline form, naturally occurring, in many colors that produce different types of gemstones.

What is Fused Quartz/Fused Silica?

Fused quartz and fused silica is glass consisting of fused silica in an amorphous solid, it has a non-crystalline form. It has very little impurities compared to other forms of glass that have materials added which lower the working temperature. Thus, absent the added impurities, fused quartz and fused silica have very high working temperatures and are able to be used in many applications such as semiconductor fabrication and laboratory equipment.

The difference between fused quartz and fused silica:

Fused quartz starts with high purity quartz, or other SiO2 containing minerals that are fused using various heat sources. Any of the resulting products manufactured using this method are referred to as fused quartz. There are two methods for producing fused quartz: electric fusion and flame fusion. The electric fusion is the most commonly used melting process for manufacturing fused quartz glass. We use fused quartz as it has a very low OH (hydroxl) content which helps retard devitrification. One example of fused quartz is GE 124.

Fused silica starts with a vapor cloud containing silicon chemicals that when burned with oxygen produces SiO2. The nano-particles of SiO2 are referred to as 'soot'. Because the chemicals are specifically produced and refined, they are available in exceptionally high purity and the resulting fused silica has a very low metallic impurity content, but can have a higher OH content as a result. The process by which fused silica is produced is called chemical vapor deposition (CVD). One example of fused silica would be Corning® 7980.

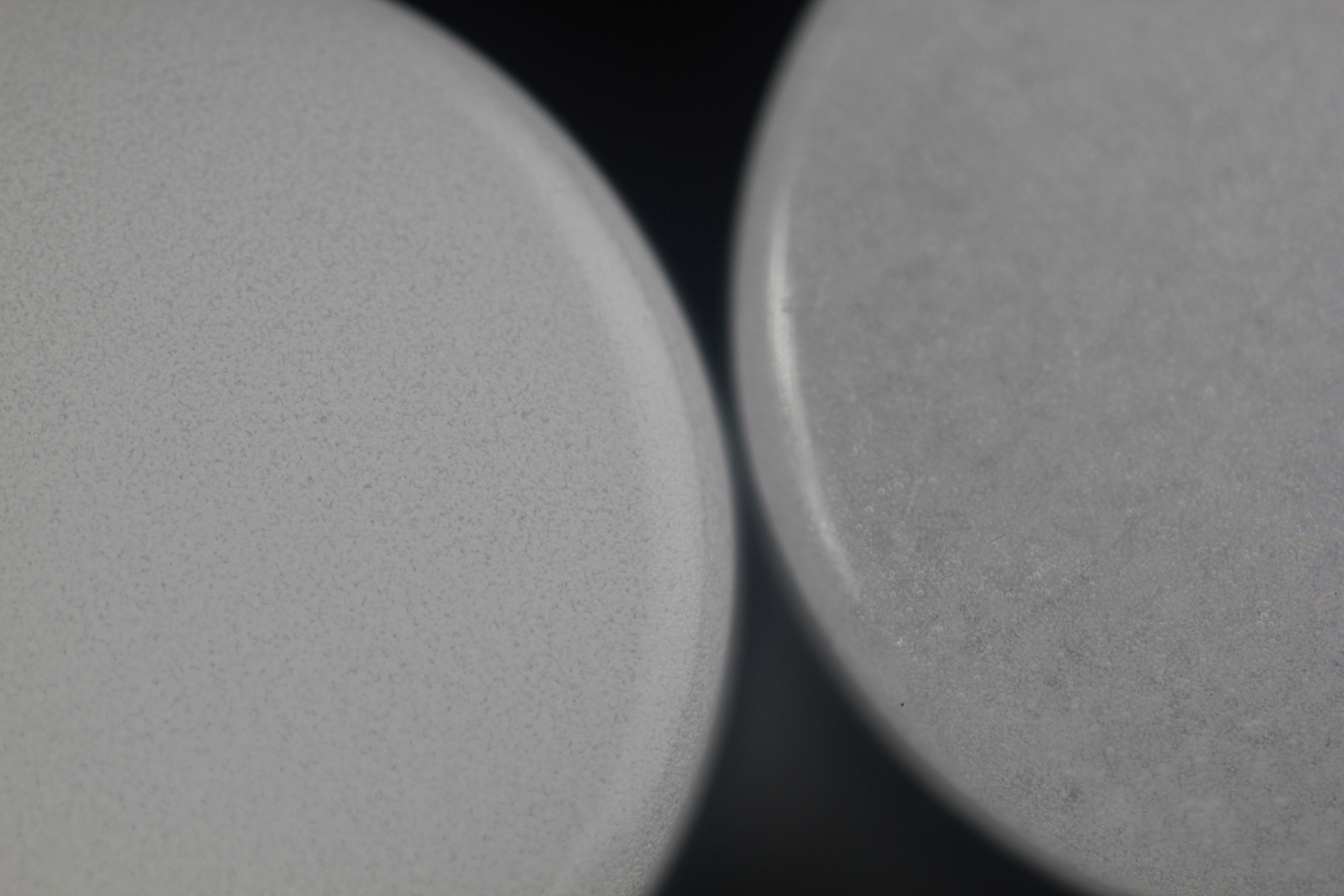

Product Quality of Fused Quartz and Fused Silica:

To keep these varieties of fused quartz and fused silica straight manufacturers have different grades and labels for the products they produce. Besides manufacturing process, the factor that separates different grades of fused quartz glass is typically defined by the trace elements left in the material. These trace elements are only a few parts per million each but can differ depending on the manufacturing process. Product purity is therefore mostly determined by the extent of refinement of the raw material and the quality control of the manufacturer. This is why it is important that only highly refined quartz precursors in conjunction with rigorous quality control is used to ensure the highest purity end product. This is why we only deal with trusted manufacturers who have a proven track record of servicing numerous industries with high quality materials.

What difference does it make:

For our applications, it is ideal to have a high purity material that has a very low OH (hydroxyl) content and reduced alkali elements to below 1 ppm. Low hydroxyl content increases the materials viscosity. Higher viscosity means less movement in the material which creates an increased maximum use temperature and helps prevent devitrification. Devitrification is also prevented by the reducing atmosphere used during manufacturing, causing the material to be oxygen deficient.

In semiconductor fabrication, manufacturers can lose entire wafers due to a single metal contaminant being present in the process, so high purity materials is quintessential to their process and bottom line.

Devitrification, or chazz as your friends probably call it, is discussed further in this earlier blog post. Though most devitrification users will experience is from burning remnant oil or other contaminants onto the fused quartz surface, contaminants inside the fused quartz can also speed up the devitrification process. A high purity material with low alkali elements will not devitrify at the same rate as a low purity material with a high OH content. High purity materials subsequently have a longer life span when put through thousands of heat cycles with proper maintenance.