Black Spots on Your Opaque Gavel. How They Got There. How To Prevent It.

If you are reading this blog it's probably because you have developed black spots inside of your Gavel and your curiosity brought you here. Well I'm happy to oblige. Today we are going to take a look at what they are, why they develop, and how to prevent them from occurring.

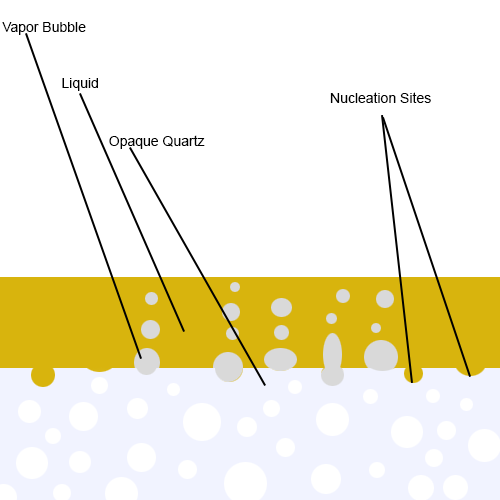

To understand what they are we must first start by examining the surface which we are trying to keep clean. One of the obvious reasons opaque is different from clear quartz is due to the multitude of gaseous air bubbles within the opaque. When these bubbles intersect with a surface plane a micro crater/nucleation site is created on the surface.

These nucleation sites cover the surface of the opaque and can vary in position, placement, and size. Depending on these factors, each nucleation site will have its own difficulty level with cleaning.

Like fingerprints, no two opaque surfaces are identical. The result is a micro textured surface which is very active during boiling and is a basic principle behind the functionality of the Gavel.

Although a micro textured surface is a benefit to the boiling process it does require more maintenance work to keep clean. So lets talk about your black spots.

How Did They Get There?

Any novice user knows that when you burn residual oil on quartz it turns black. Well this is no difference than what is occurring with black spots on the opaque. When the black spots occur, the location is generally inside the nucleation sites on the opaque surface. They occur very simply by burning oil in the site. There are two separate ways to burn the oil in the site and they are:

- Placing oil in the Gavel at temperatures exceeding 600F. Or in other words, using it too hot.

- Not fully cleaning the nucleation site before reheating (most common).

Both are easily rectified by a change in usage and cleaning habits.

How To Prevent Them?

As there are two separate ways to burn the oil, there are two separate ways to prevent them. Prevention involves understanding your surface and what it takes to keep it clean. The nucleation sites are micro sized. Compared to the size of the sites, a cotton swab is enormous and will not fit inside a site.

In order to prevent the spots you will need to:

- Do not use the Gavel too hot. This results in immediate burning of the entire floor surface, including inside the sites.

- Do not reheat the Gavel until you are sure you have fully removed all residual oil from the floors surface. This usually requires using an isopropyl alcohol dunk station in order to flush the residual oil out of the nucleation site cavities. Then removing all remnant alcohol from the surface before refiring.

Making sure the surface is 100% clear of residual reclaim contaminants is the only way to prevent those contaminants from burning on the surface of the material.

Is It Possible To Remove Them?

Sure. Lets talk about the separate ways.

- If the quartz is still relatively new, usually torching the underside of the opaque for 30-40 seconds will result in the burning away of carbon contamination in the sites. This is not an ideal long term solution because the repeated burning of contaminants on the surface can result in devitrification and graying in those areas. On older quartz the spots may remain gray. This is a sign that the site has already experienced devit and is likely not the result of a residual carbon contaminant in the site.

- Soaking the item in a hot bath of your favorite quartz cleaning solution. (Please read our cautionary blog on quartz cleaning solutions before experimenting with them.)

- If the spots are unable to be removed via steps 1 or 2 then we do always offer an in-house refurbishing service where we are able to remove all contamination stains, scratches, devitrification etc. As this service costs you both time and money it is usually suggested as a last resort. This service is for Highly Educated Gavels only, if you are interested fill out our Refurbish/Repair Waiver Form.